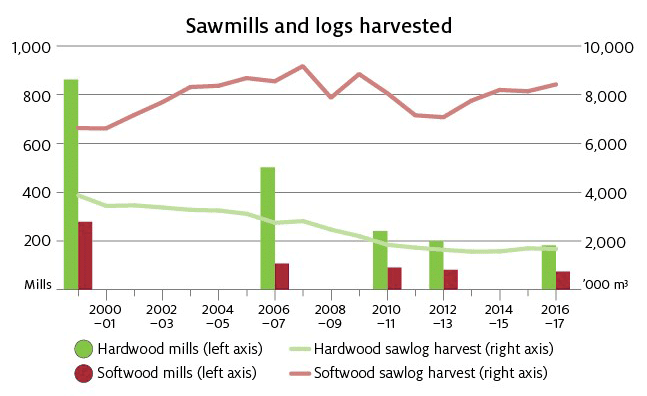

Australia’s wood processing sector consisted of 299 businesses in 2016-17. Some thriving, some stable and others under severe stress, processor numbers are down significantly on a decade earlier. Processors comprised 182 hardwood sawmills, 58 softwood sawmills, 23 wood-based panel mills, 19 post and pole mills and 17 cypress pine sawmills. With processor numbers falling, log harvests were also down on a decade earlier: hardwood by 38% and softwood by 2%.

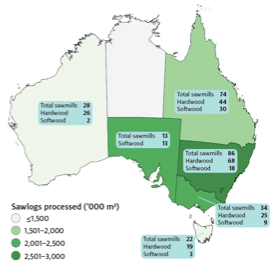

The number of sawmills in Australia has decreased significantly since 2006–07, with hardwood sawmills decreasing by 64 per cent and softwood and cypress pine sawmills by 31 per cent. The map below shows where the sawmills are situated.

In 2016–17 a total of 10.63 million cubic metres of sawlogs was processed in Australian sawmills, which comprised 1.91 million cubic metres of hardwood sawlogs, 8.58 million cubic metres of softwood sawlogs and 147,000 cubic metres of cypress pine sawlogs.ABARES reported that the volume of hardwood and softwood sawlogs harvested for domestic processing has also decreased by 38 per cent and 2 per cent, respectively, over the same period. However, the decline in mill numbers has slowed since 2012–13 and total sawlog processing volumes have increased.

The chart below displays this detail in aggregate. It demonstrates both the decline in the number of mills (especially severe for hardwood mills) and changes in logs harvested for domestic processing.

Of interest is the implied yield from the logs harvested for domestic processing. This is accentuated in the information set out below.

A total of 4.71 million cubic metres of sawnwood was produced in 2016–17, comprising 742,000 cubic metres of hardwood sawnwood, 3.91 million cubic metres of softwood sawnwood and 57,000 cubic metres of cypress pine sawnwood. In 2016–17 an estimated 280,000 cubic metres of posts and poles and 1.79 million cubic metres of wood-based panels was produced.

In 2016–17 around 27 per cent of hardwood sawnwood production was dry appearance-grade products, followed by green structural (24 per cent) and green other (24 per cent). In contrast, around 52 per cent of total softwood sawnwood production was dry structural-grade timber, followed by green other (23 per cent) and dry other (18 per cent).

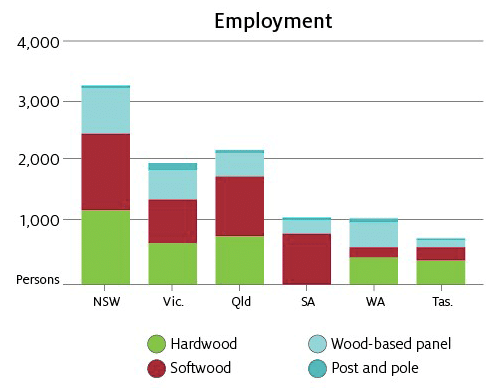

ABARES estimates that Australia’s sawmills and post and pole mills employed 8,029 people in 2016–17, of which around 89 per cent were full-time workers (including managers and owners). Males accounted for around 90 per cent of the workforce. Cypress pine sawmills employed the highest proportion of part-time workers (14 per cent) and softwood sawmills employed the lowest (8 per cent). Wood-based panel mills employed a total of 2,390 people in 2016–17. The chart below shows estimated employment levels by sector.

Perhaps unsurprising given all the foregoing material, the most common issue facing Australian mills was log supply (43 per cent of responses), followed by skilled labour (17 per cent) and mill costs (13 per cent). Other issues included the quality and size of logs, product demand and log costs.

For full details, click here.