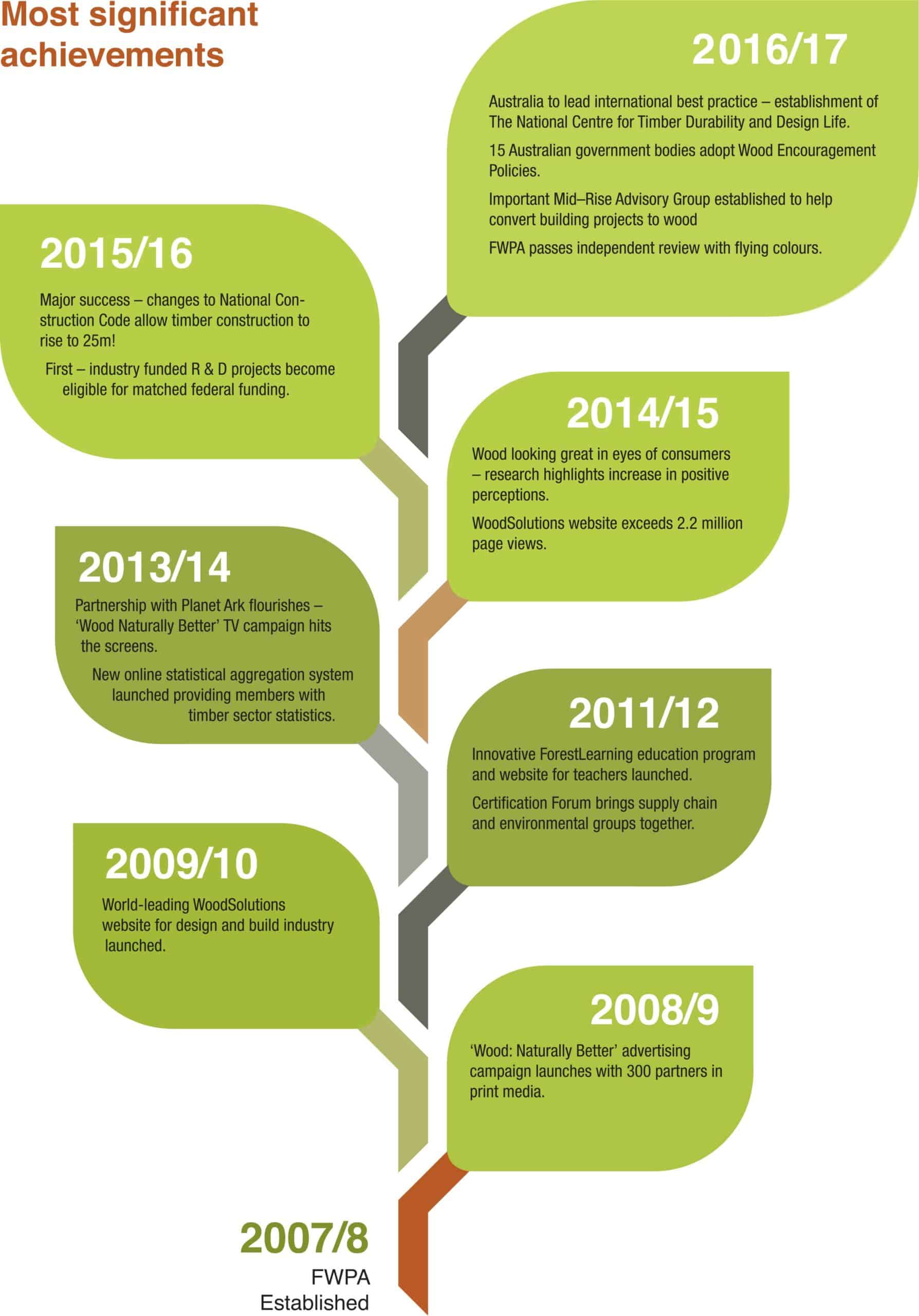

The numbers tell a story when it comes to FWPA’s 10th anniversary. From developing a world-leading timber information website, to large-scale marketing initiatives and lessons for the next generation, here’s a look at what we’ve achieved so far.

FWPA was established in September 2007, replacing the Forest and Wood Products Research and Development Corporation.

The industry-led change paved the way for an organisation with a mandate to do more than simply research – one enabled to promote and market, expand industry skills, develop codes and much more.

Marketing

One of the first marketing initiatives was the Wood. Naturally Better advertising campaign – which still continues to this day, albeit switching from print media to online and TV.

The campaign has seen consumer acceptance of wood as an environmentally friendly material rise from 56 per cent in 2008, to 77 per cent in our tracking survey earlier this year.

FWPA has developed an excellent relationship with Planet Ark, who now co-brands the consumer advertising campaign that links with their Make It Wood initiative.

However, when it comes to building materials, consumers are often guided by architects and other design and build specifiers – leading FWPA to establish WoodSolutions.

The WoodSolutions website was designed to provide one-stop-shop information on timber, and to promote its use.

Since it was established in 2009-10, the website has grown to be the world’s #1-ranked source of timber information with a total of over six million page views and 115,200 documents downloaded so far.

Other initiatives to promote the use of timber in building have included bringing leading architects internationally to Australia, and international tours for the design and build industry to learn what timber is capable of.

The marketing has paid off according to an independent 2016 review, which found a return of $6.60 on every dollar invested by FWPA in wood promotion.

Statistics, standards and codes

FWPA is working to improve members’ access to accurate industry data, to aid decision making and provide benchmarks against which their companies can be measured.

The online statistical dashboard established in 2014 now has 43 industry organisations contributing data for aggregation, producing 15 data series on subjects including safety, exports, imports, softwood, hardwood and more.

In addition to developing and contributing to new and existing codes and standards, FWPA also works to remove impediments to the use of timber.

For example, in 2015-16, the National Construction Code changed to facilitate timber construction to 25m under a “deemed to satisfy” solution – based on an application made by FWPA.

We have subsequently appointed a Mid-Rise Advisory Group, which has identified 200 planned building projects with the potential to “convert” to timber.

FWPA is also working towards a 25m “deemed to satisfy” approach for other building classes.

Research and development

Thanks to FWPA, industry-funded research projects have in the last couple of years become eligible to receive dollar-for-dollar matched funding from the Federal Government.

It’s a vital change that brings government support for our industry in line with that offered to similar bodies.

The voluntary funding matched program adds to funds FWPA already invests in research projects in a wide range of areas, including tree genetics, biosecurity, water use, timber performance, residue use and more.

It’s important to note that FWPA does not conduct research and development, but consults with members to decide which research projects to fund.

It’s hard to outline briefly the many research breakthroughs, large and small, funded by FWPA.

However, some tools and projects which have received our funding or co-funding of relevance to growers include:

- TREEPLAN – a software tool developed by the Southern Tree Breeding Association to identify the best plant genetics based on tree performance. Members can expect an ROI of 10-14 per cent for radiata pine, and 17-28 per cent for blue gum.

- Lidar and digitised photogrammetry systems, offering massive cost savings.

- Technologies to extract value from the Eucalypt genome, with more than 100 markers linked to traits such as stiffness, pulp yield and disease resistance.

- Climate change modelling, so growers understand the likely effect in terms of fire, pests and disease.

- Characterising, conserving and capturing samples of the full genetic diversity of the Australian radiata pine resource. If a future pest or disease incursion wipes out the estate, this will enable the reconstruction of breeding stock.

For processors:

- Dynamic kiln schedules – by continuously tweaking kiln temperatures, humidity levels and air flows, sawmills can save over 40 per cent of energy and even improve final product quality.

- The Cant Opti system – enabling mills to characterise the inner section of the log, saving money because low quality material is not sent for further cost-adding processing. This has been shown to add up to $14 per cubic metre to production output.

- A new CSIRO system to allow for the application of powder coating to solid wood sections will enable ‘permanent’ coatings to be applied to wood surfaces – excellent for higher level window and trim installations and eliminating the costly need for regular repainting (scaffolding systems and working at height costs).

For importer wholesalers:

- Fire and acoustic research that went into the National Construction Code change of 2016 facilitated timber construction up to 25m in class 2, 3 and 5 – a large growth in market applications for wood.

- Development and publication of the first industry-wide Environmental Product Declarations (EPDs) covering five classes of Australian timber products.

Education

From schools through to universities and ongoing professional development, FWPA funds a range of educational programs.

In 2011/12, the ForestLearning program and website was established to educate the next generation through providing a growing range of quality teaching resources.

Fast-forward to today, and ForestLearning is reaching 50,000 students a year and has 6500 teachers on its database.

The resources include topics on forest production, pests and diseases, carbon sequestration, technology and subsystems.

WoodSolutions timber education program successfully encourages universities and TAFEs to include timber engineering subjects and use the educational resources available. In the past year Deakin University, the University of New South Wales and the University of Queensland have all introduced new subjects.

The year just gone has also seen the introduction of the Centre for Timber Durability and Design Life – a collaboration between academia, government and industry based at the University of the Sunshine Coast. It is designed to keep Australia at the global forefront and develop future leaders.

FWPA has also recently established the WoodSolutions Campus, which offers professional development for the supply chain and design and building professionals.

We’re certainly not resting on our laurels in the education area, with a number of new initiatives set to be launched in the next year. So watch this space!